Solid-state Lithium Metal Battery

Solid-state Lithium Metal Battery (ssLMB)

What is ssLMB?

- Lithium Ion Battery (LIB): The global rechargeable battery market reached $98 billion in 2023 and is projected to grow to $245 billion at a CAGR of 16.3%. LIBs currently dominate with a 46% market share. LIBs utilize a liquid electrolyte to facilitate lithium ion movement between an anode and a cathode, but face several challenges: limited energy density (less than 250 Wh/kg), restricting electric vehicle driving range to around 300 miles; safety issues due to the flammability of liquid electrolytes; operational constraints related to temperature, charging speed, and lifespan; and significant costs associated with essential materials such as lithium, cobalt, and nickel

- Solid state battery (SSB): SSB replaces commercial liquid electrolytes with solid electrolytes to improve energy density, safety, and operating constraints. Solid electrolytes also function as the separator, which is essential for LIBs, and eliminate the need for cooling devices, increasing cell volume and overall energy density

- Li metal anode: The anode of ssLMB contains only Li metal as opposed to the LIB anode, which contains carbon material and/or silicon. Li anode has the highest energy density and may be formed in-situ without the anode manufacturing process

Challenges in ssLMB Development

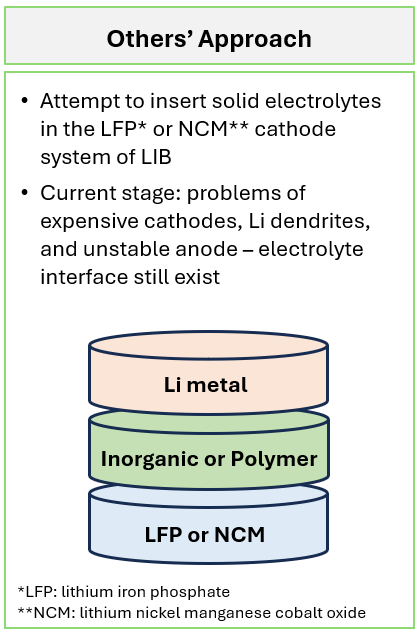

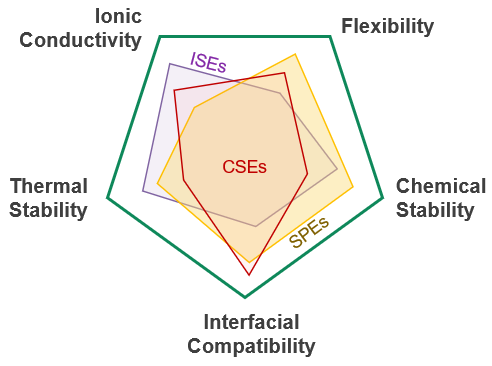

- New developments in solid electrolytes fall into three categories: inorganic solid electrolytes (ISE), solid polymer electrolytes (SPE), and composite solid electrolytes (CSE). However, finding solid electrolyte materials that meet all essential criteria—such as high ionic conductivity, thermal stability, interfacial compatibility, chemical stability, and flexibility—remains a significant challenge

- For example, ISEs typically exhibit high ionic conductivity and chemical/thermal stability but lack interfacial compatibility and flexibility. On the other hand, SPEs offer better interfacial compatibility and flexibility but may compromise on other properties

- Moreover, simply replacing liquid electrolytes with solid alternatives does not resolve issues with cathodes, such as limited energy density and high raw material costs

How Did We Tackle The Challenges?

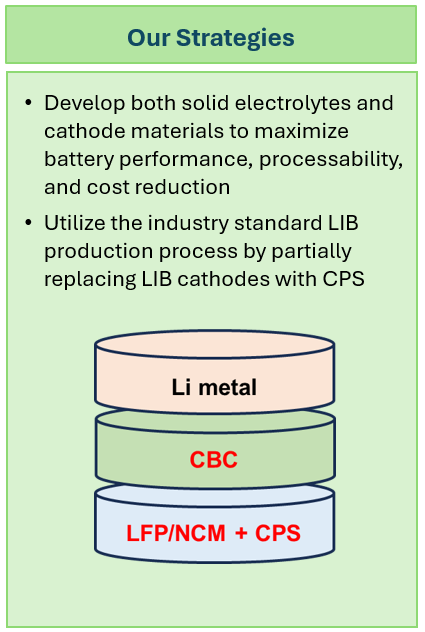

- Lincdyne’s revolutionary all-solid-state battery technology overcomes these obstacles by innovating both electrolytes and cathodes to optimize battery performance, manufacturing feasibility, and cost efficiency

- First, we pioneered a new solid electrolyte, chitosan bacterial cellulose (CBC). CBC is a polymer material that excels in interfacial compatibility and flexibility while maintaining high ionic conductivity and chemical/thermal stability. It boasts an ionic conductivity of approximately 100 mS/cm, which is 100 times higher than that of other known organic electrolytes

- Second, we developed a novel cathode material, copper phosphosulfide (CPS), composed solely of abundant materials. CPS significantly enhances energy density, offering a sustainable alternative to conventional cathode materials

- Lastly, CPS can be integrated into existing LIB production processes to enhance cathode performance, leveraging industry-standard practices while advancing battery capabilities